Speeds and Feeds Calculator

We’re pleased to announce we have a new Speeds and Feeds calculator. This new module is designed to help engineers calculate more accurately the time taken for machining operations.

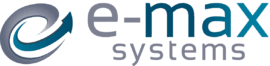

Here’s how E-Max’s Speeds & Feeds calculator works

We like practical examples so let’s look at turning an outside diameter. Our Speeds and Feeds software allows the user to select the material the finished part is made from. From this the software loads into memory the relevant cutting speed and feed rate. If you choose, these two figures can be overridden – either manually or by the speed and feed data stored against the actual tool that‘s selected for that operation.

E-Max Speeds and Feeds calculator has a simple user interface backed by powerful algorithms to give you the most accurate answers

The parameters of this turning operation – in this case, the outside and inside diameter, and the depth and the length of the cut – can then be entered into the calculator. E-Max’s Speeds & Feeds software then calculates the time the operation is expected to take – job done!

Extensive Capability

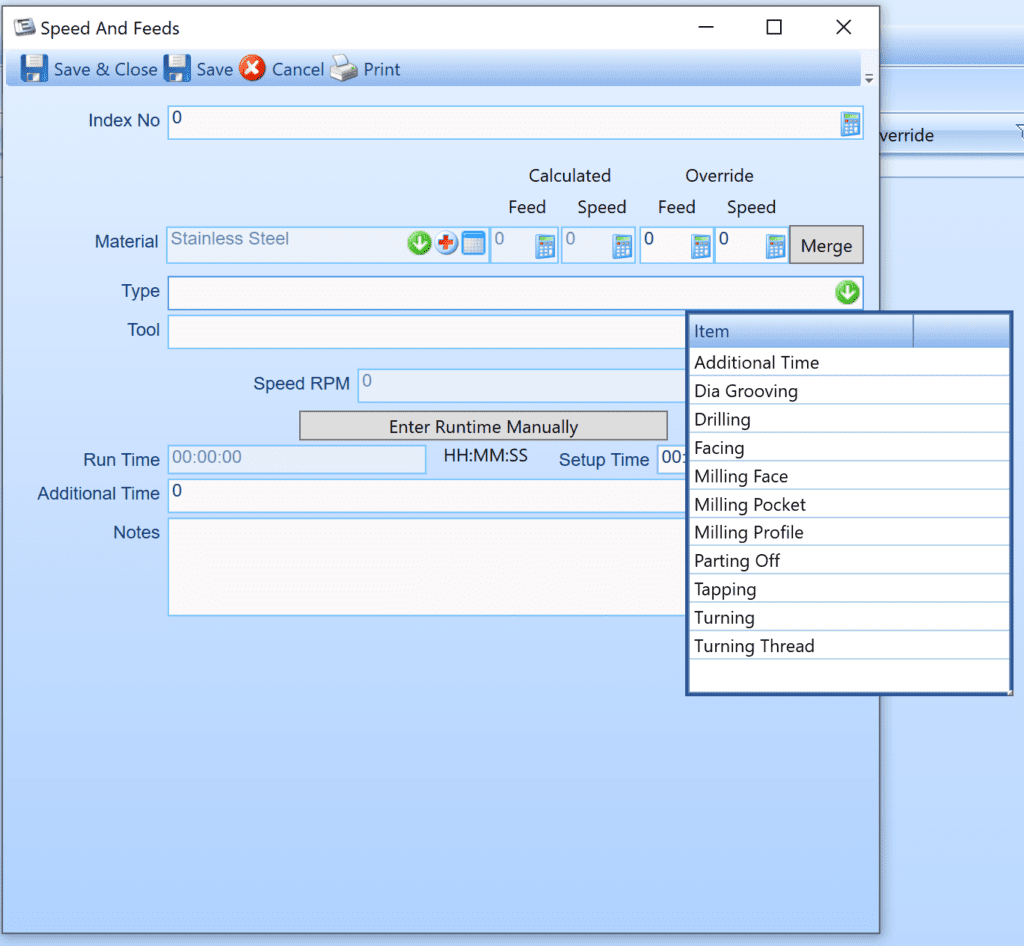

An operation on a modern CNC machine might have many varied elements ranging from turning, facing, grooving (diameter and face), drilling, tapping and even milling. E-Max’s Speeds and Feeds calculator copes with all of these types of job.

E-Max Speeds and Feeds calculator offers a wide range of activity types and tools

In the case of milling, the width and length of the slot are entered along with the depth of the cut and the diameter, as well as the number of teeth in the cutter. Once this is entered, E-Max Speeds and Feeds calculates the time expected for that operation instantly.

For items made in sheet metal, we can also use this new functionality to calculate the expected operation time of a laser operation. To do this, simply start by selecting the thickness and type of the sheet, and the laser machine that is used to make the parts. When these parameters are selected, E-Max automatically loads up the piece time and the cutting time per mm. From there, enter the shape and size of the part or, if the shape is too complex, the perimeter. Any holes, whether round or rectangular, are also entered and E-Max calculates the cutting time for that operation.

Loading time for a new sheet and a basic setup time for the machine can also be stored in E-Max.

Big Benefits of E-Max Speeds and Feeds Calculator

Rather than relying on guesswork, the Speeds and Feeds Calculator gives accurate estimations based on previous experience. Estimators and planners in a company can consider these timings in a methodical fashion and use this information as a basis to then work out, even more accurately and much more quickly, the time for each operation.

Having these accurate timescales means production managers can better schedule jobs and minimise the downtime of machines, tools and operators.

There’s another benefit to incorporating this new Speeds & Feeds Calculator into your operations. E-Max’s functionality already enables users to ES-PLAN-ACT. Now you can also save these estimated times against the planned times and then compare these to planned times (when the job is actually won and the route finalised), and the actual production time (when the job is completed) for even better future planning and scheduling.

For further information on how E-Max’s new Speeds and Feeds Calculator can benefit your manufacturing or engineering business, speak to one of our qualified team on 0141 644 4424, take a look at our website or email us.

Don’t miss out on notifications of future E-Max ERP functionality developments – sign up to be the first to know!